2025年11月,德国斯图加特和德国科堡——全球领先的汽车零部件供应商德国博泽集团(Brose)携手华曙欧洲,成功列装一款专为汽车行业高要求量身打造的金属3D打印设备。该创新设备的一个显著特点是兼容可持续性金属粉末,该粉末完全是由博泽Brose冲压车间的钢铁废料回收制成。这款高性能3D打印设备助力博泽Brose在确保产品质量和性能的前提下,实现了严格的二氧化碳减排目标。

这款定制的金属3D打印设备是基于华曙高科FS721M-8-CAMS平台,成形体积为720x420x390mm³。此外华曙高科还提供成形高度为650mm的选配。华曙为博泽Brose定制设计的这款设备,配备8个激光器,非常适合高效零部件生产。其激光功率8 x 2000 W,远远高于市场标准,这一组合使博泽Brose实现更高效的增材制造批量化生产。

图1:华曙高科FS721M-8-CAMS金属3D打印设备

该设备的一个非常独特的优势是采用了华曙高科自主研发的光束整形技术,能够高效且经济地利用高功率激光。华曙光束整形技术以环形光斑的形式适用于较大的激光光斑直径,形成非常均匀的熔池,生产出高质量部件。

该设备的另一个亮点是采用了先进的CAMS技术(连续增材制造系统),使打印完成后的工件包能够立即从设备中转运出来,然后将一个新的成形缸转运至打印设备中,开始下一次打印工作,大大缩短设备的停机时间。

除了硬件之外,该设备的软件在处理单个任务中众多部件的简便性和快速性方面也进行了进一步优化。通过这些措施共同作用,使得该设备成为一款高效3D打印系统,极大降低单个零件成本。

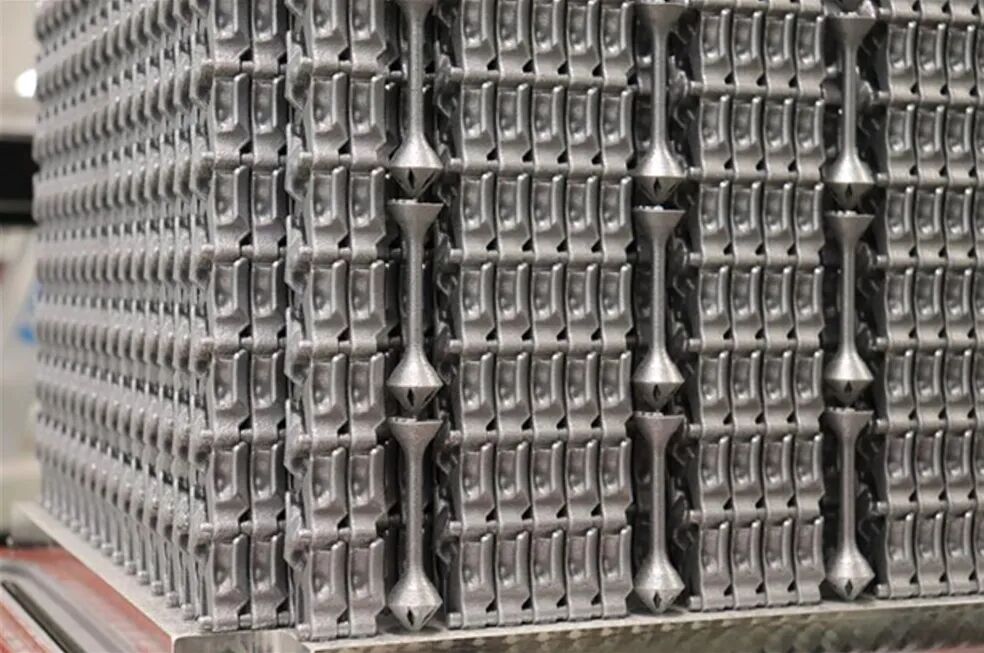

图2:博泽Brose采用FS721M-8-CAMS 设备和环保钢打印的工件包

"

采用华曙先进增材制造系统,使我们能够以更高的产能和更短的生产时间来批量生产更多产品,从而实现盈利。凭借FS721M-8-CAMS设备,现在博泽Brose能实现更大批量的生产订单,缩短生产周期,提高整体盈利能力,增材制造已成为大批量产应用的理想之选。

这款创新3D打印设备的一个突出特点是它兼容‘环保钢’,这是一种低合金钢材料,符合我们对可持续生产的承诺。

Eric Fritzsche

博泽Brose增材制造负责人

"

通过与Brose博泽合作,我们将创新转化为真正的生产效率,这是强强合作和开源理念达成成果的绝佳范例,是材料、零部件设计与3D打印设备的完美结合,对于增材制造未来而言也是一个非常有价值的里程碑。

Oliver Li

华曙高科欧洲公司总经理

如您有任何疑问,欢迎莅临Formnext 2025展会华曙高科展台咨询,展位号11.0-E11。该展会将于11月18日至21日在德国法兰克福举行,是工业级3D打印领域最大的展览会。

关于博泽Brose

博泽是德国汽车零部件行业中最大的私营企业。每三辆新车中就至少有一辆配备了博泽的产品。该公司是机电一体化专家,研发并制造用于车门、挡板和座椅的系统。此外,博泽还生产电动机,功率范围从200瓦到14千瓦,用于转向系统、热管理和电动滑板车等广泛应用。该家族企业在全球24个国家68个地点拥有约31,000名员工。2024年,博泽集团实现销售额77亿欧元。

关于华曙高科

华曙高科成立于2009年,是一家工业级高分子和金属增材制造系统制造商。该公司采用开源参数策略、配备高性能硬件,并通过华曙欧洲公司提供本地化支持,从而帮助客户以高质量、高灵活性和低成本实现增材制造的规模化应用。

Farsoon and Brose are setting new standards in metal 3D printing

November 2025, Stuttgart and Coburg (GER/GER)——Farsoon Europe GmbH has teamed up with Brose to develop a metal 3D printer tailored to the high demands of the automotive industry. One outstanding feature of this innovative printer is its compatibility with sustainable metal powder. It is made entirely from recycled steel waste from Brose's own press shops. The high-performance 3D printer helps Brose meet strict CO2 targets without compromising on quality and performance.

The newly developed metal 3D printer is based on the FS721M-8-CAMS system with a build volume of 720x420x390 mm³. Farsoon also offers the system with an optional build volume height of 650 mm. Farsoon designed the system for Brose with eight lasers – ideal for efficient component production. At 8 x 2000 watts, the laser power is well above the market standard. This combination enables Brose to achieve significantly more efficient additive series production.

A very unique feature is Farsoon's patented special ‘beam shaping’ technology. The use of beam shaping technology enables efficient and profitable utilisation of the high laser power. Beam shaping works with larger laser spot diameters in the form of a circular ring, which, among other things, results in a very homogeneous melt pool and ultimately high-quality components.

Another highlight is the advanced CAMS technology (Continuous Additive Manufacturing System). This allows the finished print job to be removed from the machine immediately after printing. A new build container is then inserted into the machine. This ensures that laser downtime, during which no work can be done, is minimised.

In addition to the hardware, the software has also been further optimised in terms of the simple and fast handling of many components in a single job.All these measures together make the system a highly efficient printer that achieves the lowest possible component costs.

Fig. 2 shows a construction job printed on the Farsoon FS721M-8-CAMS with high packing density. The construction job contains more than 21,000 components, which are manufactured without support structures. During component design, care was taken to ensure that component post-processing could be carried out fully automatically without manual processes.

If you have any questions, please visit us at this year's Formnext in Frankfurt/Main in Hall 11.0, Stand E11. The central trade fair for industrial 3D printing will take place from 18 to 21 November in Frankfurt am Main.

Quote from Brose:

"The advanced system supplied by Farsoon enables us to profitably produce larger series thanks to higher throughput and shorter production times. With the FS721-8-CAMS, Brose can now produce more components per production order, shorten cycle times and increase overall profitability – making additive manufacturing an economical solution for high-volume applications," explains Eric Fritzsche, Head of Additive Manufacturing. “An outstanding feature of the innovative 3D printer is its compatibility with ‘Green Steel’, a low-alloy steel material that supports our commitment to sustainable production.”

Quote from Farsoon:

“Together with Brose, we turned innovation into real production efficiency — a great example of what strong partnership and open technology can achieve,” said Oliver Li, Managing Director of Farsoon Europe. “The combination of material, component design and perfectly matched printers thus represents a very valuable milestone for the future.”